Line of machines for the PU casting for the assembling of air filters of different type and shape and to mould:

- gaskets in semi-expanded PU for panel filters with any profile;

- frames in rigid PU for absolute and bag filters;

- technical items in semi-expanded or rigid PU.

The plant is composed of tested and reliable modules combined to satisfy different productive needs:

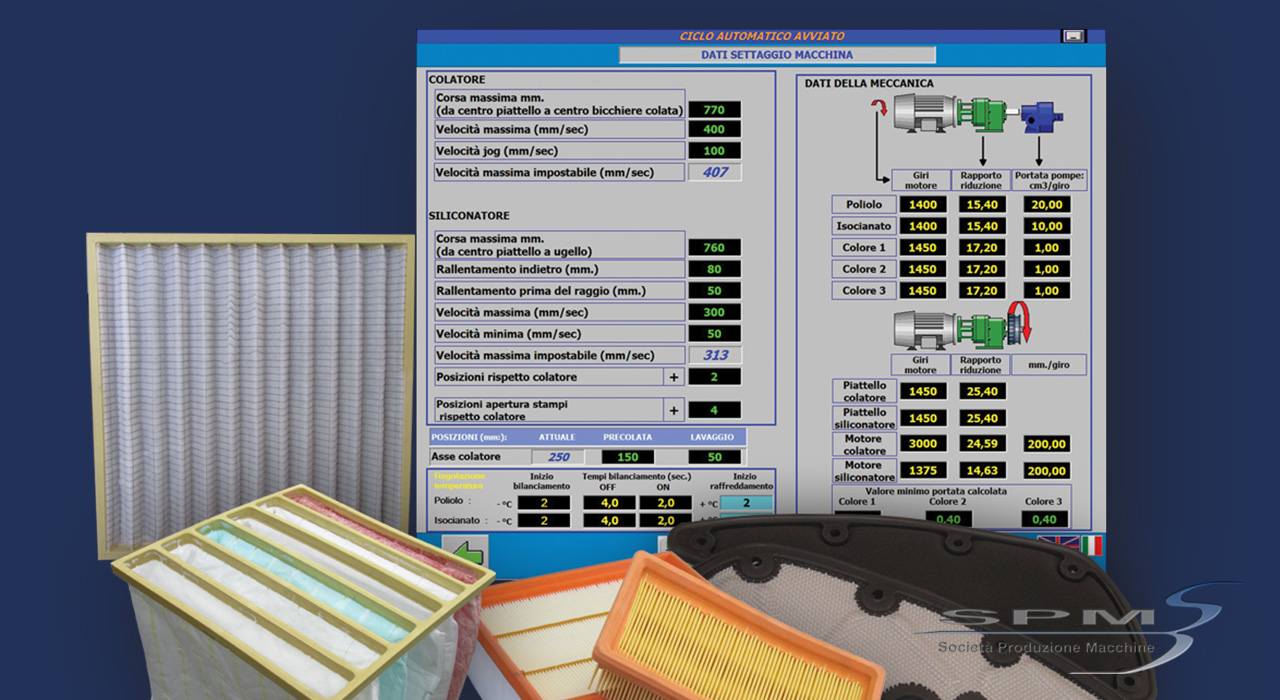

- Metering unit with two or more thermo-regulated tanks with precision pumps at programmable output; with the possibility of sending to the casting different

polymers (rigid and semi-expanded or coloured) operating on the functions controlled by the control unit; - Casting unit at 2 interpolating axes “X-Y” to program the distribution path with the opportunity to implement the third axis “Z”;

- Mixing head fully in treated steel, specific for each output from 5 to 200 gr/sec., produced according to technologies tested and refined by decades of S.P.M.

experience; - Standard rotating table at 14, 18, 24, 48 stations, driven by a highly precise electromechanical device;

- Thermo-regulated mould-holder stations, with closing system able to support 2 tons, for moulds up to 600×800 mm.;

- Controlling unit equipped with PLC + PC, with colour display for the control of the complete plant and the memorization of the casting paths and of the parameters for the dosing and the mixing of the reagents.